Hardware features

SHARED ELECTRONICS FOR ALL EVOLUTION MACHINES

- Machine equipped with three sidewall cameras to make precise measurements on body external profile

- Equipped with additional finish cameras for finish measurements

- Provides the advantages of non-contact online inspection

- 360° vision on the production line

Defect list

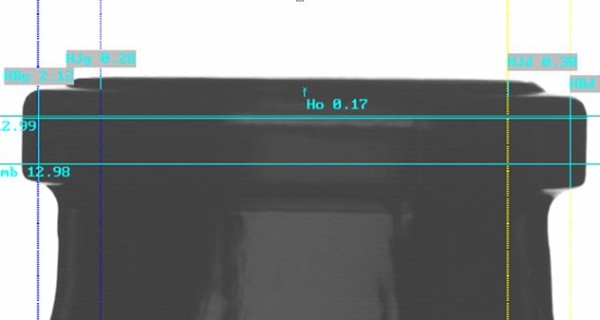

EVOLUTION DIM MEASURES ACCURATELY:

- article height

- minimum and maximum diameters

- roundness and barreling

- non-round sidewall,

- diameter deformation

- bulged or sunken sidewalls

- out-of-specification height

- tiny body deformations and minor geometrical defects on the body

- minimum and maximum finish external diameter

- finish height

- height of the finish ring

- finish flatness

Software inspection tools

Technical specifications

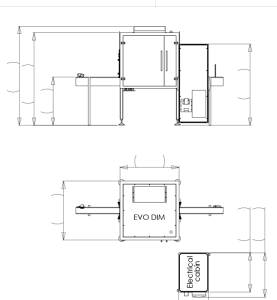

PRACTICAL INFORMATION NECESSARY FOR EVOLUTION DIM INSTALLATION

ELECTRICAL

| Power supply : | 230V 50/60Hz |

| Installed Power : | <3,2 kW |

| Fuse of line : | 16A |

| Number of Phases : |

COMPRESSED AIR

| Compressed Air : | 5-6 bar |

| Type of connection : | Air 3/8″ |

| Maximal consumption of air : | < 900Nl/min (calculated for a speed of 600bpm with 100% rejection) |

WEIGHT

| Weight of machine packed : | Approx. 600kg |

| Weight of machine : | Approx. 450 kg Dimensions |

DIMENSIONS

| Lenght : | 1200 mm |

| Width : | 1200 mm |

| Height: | from 1880 mm to 2080 mm (for a conveyor height between 900 mm and 1100 mm) |

| Charge on the ground : | 1,1 kg / cm2 |

TELEMAINTENANCE CONNECTION

| Access to internet or directly, or using the plant network. The machine has to be seen from outside of the plant using IP address given to IRIS Inspection machines. |

INFORMATION SYSTEM

| Connection to the production information system via protocol Modbus on Ethernet or on RS232/RS485. The machine can send a reject signal to the production information system, keep record and provide report as real time basis. |

NETWORK

| Machines can be connected altogether via Ethernet network to compare adjustments, to copy parameters… |