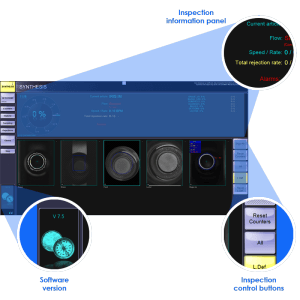

Hardware features

MULTIPLE INSPECTION TOOLS IN ONE MACHINE

- Motorized cameras with automatic repositioning to secure repeatability

- No optical and/or mechanical adjustments needed

- Machine design allows an easy access to all inspection stations

- Up to 600mm bottle’s height with the XXL option

- Mould number reader suitable for all standard mould codes (alphanumerical, dot codes, heel dot codes, AGR codes)

Optical design

REVOLUTIONARY CONCEPT

- New HD cameras improving accuracy

- New PC for more powerful imaging

- New HD touch screen (21,5”) improving settings and monitoring

- LED light source with different lighting anglesOptimized for all types of glass: from very dark glass to flint glass and ultra-white glass

Software Inspection Tools

INNOVATION OF INSPECTION TOOLS

In addition to the conventional inspection tools, the newest inspection algorithms are available in Evolution5 for even better inspection of your articles. Choose the inspection modules fitting your need

Technical specifications

PRACTICAL INFORMATION NECESSARY FOR EVOLUTION 5 INSTALLATION

ELECTRICAL

| Power supply : | 380V 50/60Hz |

| Installed Power : | <5 kW |

| Fuse of line : | 20A |

| Number of phases : |

COMPRESSED AIR

| Compressed Air : | 5-6 bar |

| Type of connection : | Air 3/8″ |

| Maximal consumption of air : | < 900Nl/min (calculated for a speed of 600bpm with 100% rejection) |

WEIGHT

| Weight of machine packed : | Approx. 1000kg |

| Weight of machine : | Approx. 900 kg Dimensions |

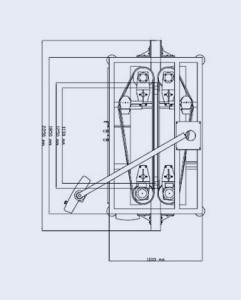

DIMENSIONS

| Lenght : | 1850 mm |

| Width : | 1100 mm |

| Height: | from 1880 mm to 2080 mm (for a conveyor height between 900 mm and 1100 mm) |

| Charge on the ground : | 2 kg / cm2 |

TELEMAINTENANCE CONNECTION

| Access to internet or directly, or using the plant network. The machine has to be seen from outside of the plant using IP address given to IRIS Inspection machines. |

INFORMATION SYSTEM

| Connection to the production information system via protocol Modbus on Ethernet or on RS232/RS485. The machine can send a reject signal to the production information system, keep record and provide report as real time basis. |

NETWORK

| Machines can be connected altogether via Ethernet network to compare adjustments, to copy parameters… |